Fibre Identification and Material Analysis in Textile Applications

Forensic microscopy and chemical characterisation in quality assurance and dispute investigation.

Relevance of textile analysis

Textiles are used worldwide in industrial, medical, defence, consumer and packaging contexts. The quality, origin and composition of textile elements are crucial for product functionality and safety claims. When deviations occur in products or processes, textile analysis offers an objective method to:

- determine the type of fibre or fabric

- verify supplier material claims

- explain damage or wear

- substantiate contamination or mixing errors

TLR supports this assessment with accredited laboratory analyses under ISO/IEC 17025 (RvA L059). Reports can be used in technical files, audits, liability cases and product recovery.

Application areas

1. Fibre identification

- Purpose: determine the type of textile fibre (e.g. cotton, viscose, polyester, polyamide)

- Technique: polarisation microscopy combined with colour reagents

- Application: verification of claims such as '100% natural' or 'synthetic-free'

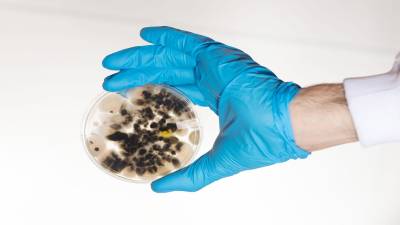

2. Contamination investigation

- Purpose: identify foreign fibres or material traces in product environments

- Examples: fibre fragments in packaging lines, protective clothing, cleaning materials

- Relevance: recalls, customer complaints, origin investigation

3. Damage and wear analysis

- Purpose: explain defects such as melting, discolouration, breakage or delamination

- Use: support in supplier disputes, damage claims, insurance investigations

4. Origin and forensic analysis

- Purpose: determine the origin of textile residues or unknown fibre material

- Application: identification for liability, quality assurance or trace-back

Analytical techniques and interpretation

Method | Application |

Polarisation microscopy | Morphological fibre identification |

Colour reactions with reagents | Chemical characterisation of fibre type |

Microscopic damage classification | Analysis of breakage, melt or friction marks |

Fibre matrix assessment | Complex structures such as non-wovens, blends |

Note: For processed or charred fibres, interpretation may be limited. Matrix homogeneity and physical damage affect the reliability of identification.

Standards and reporting framework

- Performed under ISO/IEC 17025 accreditation (RvA L059)

- Use of standardised reference collections

- Reports suitable for:

- complaint files and supplier deviations

- technical product documentation

- export and insurance documentation

- origin investigation and legal proceedings

Case study: fibre residues in consumer packaging

A producer of plastic consumer packaging found fibre residues in sealed end products during an internal quality inspection. Classical chemical analysis provided no conclusive results. Microscopic examination at TLR identified polyamide fibres originating from thermal sealing fabric inside the sealing machine. The supplier was informed, cleaning protocols were tightened, and traceability was restored.

Conclusion

Textile analysis through microscopy and fibre chemistry offers a specialised solution for material verification, contamination investigation and damage classification. TLR provides substantiated laboratory results to clients in sectors where textile properties are a key factor in quality, safety and legal robustness.

Meld je aan voor de laatste tips en adviezen dat je gelijk in de praktijk kunt brengen.