Scrutinizing Textile Claims with Fiber Identification and Material Analysis

When certainty about fibers makes the difference between trust and doubt in your supply chain

Why material knowledge is becoming increasingly important in textiles

The textile sector is under pressure. Consumers demand transparency, brands communicate about sustainability, and certifications determine market access. In this context, the demand for objective material analysis is increasing.

Fiber identification helps to determine exactly which raw materials are actually present in a fabric. This is essential for quality control, contract validation, certification verification, and dispute resolution.

What does fiber identification involve?

Fiber identification is the determination of the type of fibers in a textile sample. This is done through:

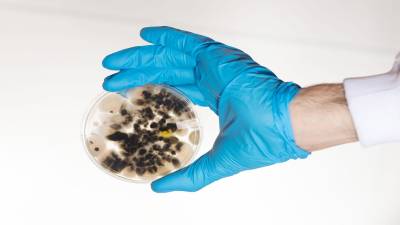

- Microscopy: visual comparison of fiber structure

- Burn and solubility tests: characteristic behavior when heated or in chemical reagents

- FTIR spectroscopy: analysis of molecular bonds for synthetic fibers

- DNA or GMO tests: detection of genetically modified cotton or origin verification

These methods make it possible to distinguish between cotton, polyester, viscose, wool, linen, acrylic, and blended compositions.

Case: unexpected polyester mix in “100% cotton” textiles

An importer of bed linens had samples tested after a retailer complained about pilling and shrinkage. According to the label, the material was 100% cotton. Fiber identification, however, showed that the fabric consisted of 35% polyester.

The error was traced back to the spinning mill: leftover material from other batches had been reused without updating the label. The test report allowed the importer to substantiate the problem, reject and repackage the batch, and notify the supplier of the contract breach.

Without laboratory evidence, this would have been a difficult discussion.

When is fiber identification valuable?

This analysis is relevant for:

- Incoming goods inspection (verification of supplier claims)

- Certification audits (e.g., GOTS, Oeko-Tex, GRS)

- Complaint investigations from retailers or consumers

- Validation of specifications in private label production

- Legal substantiation in disputes or recalls

TLR is accredited for various fiber and material analyses. The combination of classic microscopic examination and modern chemical techniques ensures reliable, reproducible results.

The importance of additional material analysis

In addition to fiber type, other material properties are often examined:

- Pesticide residues (for organic claims)

- Gossypol content (in cotton seeds)

- GMO analysis (in genetically modified cotton)

- Discoloration, shrinkage, pilling (under product stress)

These parameters strengthen product information and make it possible to substantiate claims, labels, and certifications.

Conclusion: textile analysis provides certainty in an opaque supply chain

Certainty about material composition is not optional in a market where claims are quickly questioned. Fiber identification and material analysis help reduce risks, limit liability, and demonstrate supply chain control.

Ensure that you have an analysis carried out immediately in case of discrepancies or doubt. The data reveals what the label sometimes conceals.

Frequently asked questions about fiber identification

What is the minimum amount of material needed for analysis?

A swatch of 5 × 5 cm is often enough for microscopy and solubility tests. Smaller amounts can be used for DNA or FTIR tests.

Is it possible to identify blends?

Yes, blends of natural and synthetic fibers can be quantified by type and percentage.

Is this analysis carried out under accreditation?

Yes, TLR performs fiber and material testing under ISO/IEC 17025, using validated methods.

Step-by-step: how a textile analysis works

- Collect a sample of the material (preferably without finishing or coating)

- Determine the fiber structure and material composition visually or chemically

- Analyze for specific properties such as shrinkage, stretch, contamination, or GMO

- Compare with product specification, label, or contract

- Report deviations and discuss possible next steps

Meld je aan voor de laatste tips en adviezen dat je gelijk in de praktijk kunt brengen.