Keeping Fat Quality in Check with Peroxide Value and Saponification Value

Why high-quality oils are only truly reliable with the right laboratory measurements

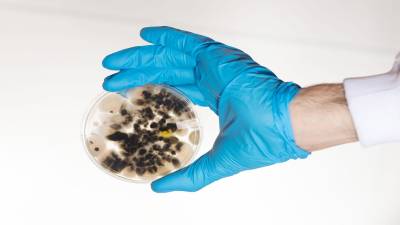

Why fats are susceptible to quality loss

Fats are an essential ingredient in countless food products. However, their quality is far from guaranteed. Storage, transport, and origin play a crucial role in oxidation, off-flavours, or reduced functionality.

Quality issues with fats are rarely detected in time—often only when products smell rancid, turn brittle, or consumers complain. Measurements such as the peroxide value and the saponification value help identify these risks at an early stage.

What does the peroxide value say about fat quality?

The peroxide value measures the amount of peroxides: the first breakdown products in fat oxidation. A higher value indicates the start or progression of spoilage, with direct consequences for aroma, taste, and shelf life.

Indicative values (meq O₂/kg fat):

- 0 to 5 = fresh fat, good quality

- 5 to 10 = beginning of oxidation

- 10 = oxidised, not suitable for consumption

This measurement is an essential indicator of freshness, but it says nothing about the original composition. That’s why it’s also important to determine the saponification value.

What does the saponification value reveal about composition?

The saponification value measures how much potassium hydroxide is needed to completely saponify the fat. This provides insight into the fatty acid chain length and thus the origin or possible adulteration.

- High saponification values indicate short-chain fatty acids (e.g., coconut oil)

- Low saponification values indicate long-chain fatty acids (e.g., fish oil)

The value acts as a fingerprint of a fat type. Deviations can indicate blending with cheaper oils or labelling errors. This analysis is often used in trade disputes or to validate specifications.

Additional analyses for fat stability

In addition to peroxide value and saponification value, other parameters provide extra insight:

- Anisidine value: measures secondary oxidation products

- TOTOX value: the sum of both, indicating the total oxidation level

- Acid value: indicates hydrolysis and free fatty acids

Ideally, these measurements are combined to assess the full oxidation profile of an oil or fat.

Case study: margarine complaint leads to revised storage protocol

A manufacturer of industrial margarine received complaints from bakers about unusual smell and spreadability. Initially, a recipe error was suspected.

Laboratory testing, however, showed a peroxide value of 12.5 meq O₂/kg, above the permitted limit. The saponification value also deviated from the reference file, indicating adulteration.

The cause was traced to a storage logistics error at the supplier. The oil had been exposed to temperature fluctuations, accelerating oxidation. In addition, the supplied sunflower oil was partially mixed with soybean oil.

With the accredited test reports, the manufacturer was able to reject the batch and hold the supplier accountable.

Who benefits from these analyses?

These fat analyses are important for:

- QA teams of food manufacturers

- Buyers of vegetable and animal fats

- Private label suppliers with export obligations

- Product developers of sauces, margarines, supplements

- Laboratories and audit teams in trade inspections

All analyses are included in TLR’s ISO/IEC 17025 accreditation (scope L059), under methods TL382.24A (peroxide value) and TL382.28 (saponification value).

Risks of skipping fat analyses

- Labelling errors go unnoticed

- Rancidity causes complaints or returns

- Fraud (adulteration) remains undetected

- Legal claims are harder to substantiate

By testing regularly, you prevent supply chain damage and protect your product’s reputation.

Conclusion: fat quality should be based on data, not smell

An oil that looks clear today may be oxidised tomorrow. By consistently measuring peroxide value and saponification value, you safeguard quality, origin, and stability. These parameters make the difference between gut feeling and analytical proof.

Have analyses carried out by an accredited laboratory to ensure results are defensible in audits, claims, and corrective processes.

Frequently asked questions about fat analyses

What is the difference between peroxide value and saponification value?

The peroxide value measures oxidation, while the saponification value provides information about the fatty acid composition.

What is the standard for peroxide value?

For edible fats, a limit of <10 meq O₂/kg is generally used, depending on the product type.

Can adulteration with cheaper oil be detected?

Yes, deviations in saponification value or iodine value can indicate blending.

Step-by-step: how a fat analysis works

- Take a representative sample of the oil or fat product

- Determine the peroxide value via titrimetry (NEN-EN-ISO 3960)

- Measure the saponification value (NEN-EN-ISO 3657)

- Compare with product specifications or standard values

- Report deviations and assess risks

- Use results for claims, corrective measures, or supply chain management

Meld je aan voor de laatste tips en adviezen dat je gelijk in de praktijk kunt brengen.