How to Prevent Baking Quality Complaints and Supply Chain Claims with a Reliable Falling Number

How a Simple Enzyme Test Explains Major Quality Differences in Industrial Bakeries

Why the Baking Quality of Wheat Flour Is Not Always Guaranteed

In the food industry, every step of the production process is carefully monitored. Yet there are situations where finished products deviate from the standard, even though the recipe and processing remain unchanged. Think of dense bread, poor rise, or an unusual crumb structure. In many of these cases, the cause lies in the raw material itself: wheat flour.

A crucial indicator for the processing properties of flour is the so-called Falling Number. This value reflects the enzyme activity in the flour and is of great importance for millers, QA managers, and industrial bakeries.

What Is Falling Number and Why Is This Analysis So Important?

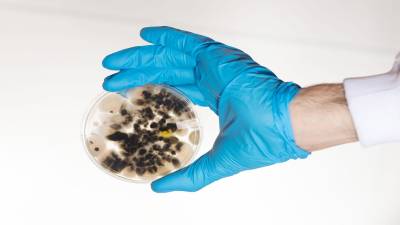

The Falling Number analysis (NEN-EN-ISO 3093) determines the activity of the enzyme alpha-amylase in flour or milled grain. Alpha-amylase breaks down starch. When this process occurs too quickly, it leads to insufficient structure formation during baking.

During the analysis, the time it takes for a stirring rod to fall through a heated starch solution is measured. High enzyme activity results in a watery solution and therefore a low Falling Number value. Low enzyme activity produces a thick paste and a higher value.

Interpretation of Falling Number Results:

- Less than 200 seconds: excessive enzyme activity, risk of sticky or dense bread

- 200 to 300 seconds: acceptable enzyme activity for standard applications

- More than 350 seconds: low enzyme activity, risk of dry crumb or underbaking

This measurement is essential for quality assessment of grain batches and flour products. It enables companies to anticipate processing behavior, ensure consistency, and prevent complaints.

Practical Example: Deviating Baking Results Due to Changed Enzyme Activity

An industrial bakery reported sudden changes in bread volume and crumb structure of a standard product. Oven settings, mixing time, and yeast dosage were unchanged. Still, the bread performed below expectations.

A Falling Number analysis showed that the flour used had a value of 190 seconds, while previous batches measured 290 seconds. This deviation indicated increased enzyme activity, likely caused by moist storage of the wheat or blending with undried batches.

Based on this result, the miller was able to trace the cause and take measures in storage and blending strategy. The bakery temporarily adjusted with a tailored premix while tightening purchasing criteria.

For Which Companies Is Falling Number Relevant?

The Falling Number analysis is widely applicable in the food supply chain:

- Grain importers use it for classification and quality control

- Flour producers set it as a standard in blends and batch acceptance

- Premix manufacturers use the value as a basis for recipe development

- Industrial bakeries monitor it to prevent volume-related complaints

- QA managers include the measurement in their raw material control plan

The analysis at TLR is fully accredited under ISO/IEC 17025:2017 (scope L059).

Conclusion: Measure Falling Number Before Complaints Arise

Small deviations in enzyme activity can have major effects on bread quality, processing behavior, and customer satisfaction. By using Falling Number analyses as a standard in the assessment of flour or grains, you can prevent supply chain issues and later claims.

Whenever possible, request analysis from an accredited laboratory such as TLR to ensure the values are reliable and reproducible.

Frequently Asked Questions About Falling Number

What is a good Falling Number value for standard wheat flour?

A value between 200 and 300 seconds is considered optimal for most bread applications. Extremes should be avoided.

How quickly is a Falling Number analysis available?

At TLR, a standard analysis is usually available within 24 to 48 hours after sample receipt.

What can affect Falling Number values?

Harvest conditions, storage climate, moisture content, and wheat type directly influence enzyme activity and therefore the Falling Number.

Step-by-Step: How a Falling Number Analysis Works

- Grind the grain sample or use flour directly

- Weigh a fixed amount and mix it with water to create a suspension

- Heat the mixture until gel formation occurs

- Let a stirring rod drop into the heated mixture

- Measure the time in seconds until the rod reaches the bottom

- Interpret the value based on the desired baking properties

Meld je aan voor de laatste tips en adviezen dat je gelijk in de praktijk kunt brengen.